Dataplas Ltd specialises in the precision machining of engineering plastics. You are provided with the comfort of a personal service philosophy, driven by a commitment to understanding your requirements for quality, design, price and turnaround time. Dataplas will assist you with expert materials selection and design advice to ensure high performance and reliability.

Selecting a particular type of plastic or grade of material may be daunting, to say the least given the wide range of engineering plastics that are available. This is where our many years of experience and extensive knowledge of engineering plastics can become invaluable in offering our customers the correct advice to ensure the best possible material is selected for their requirements.

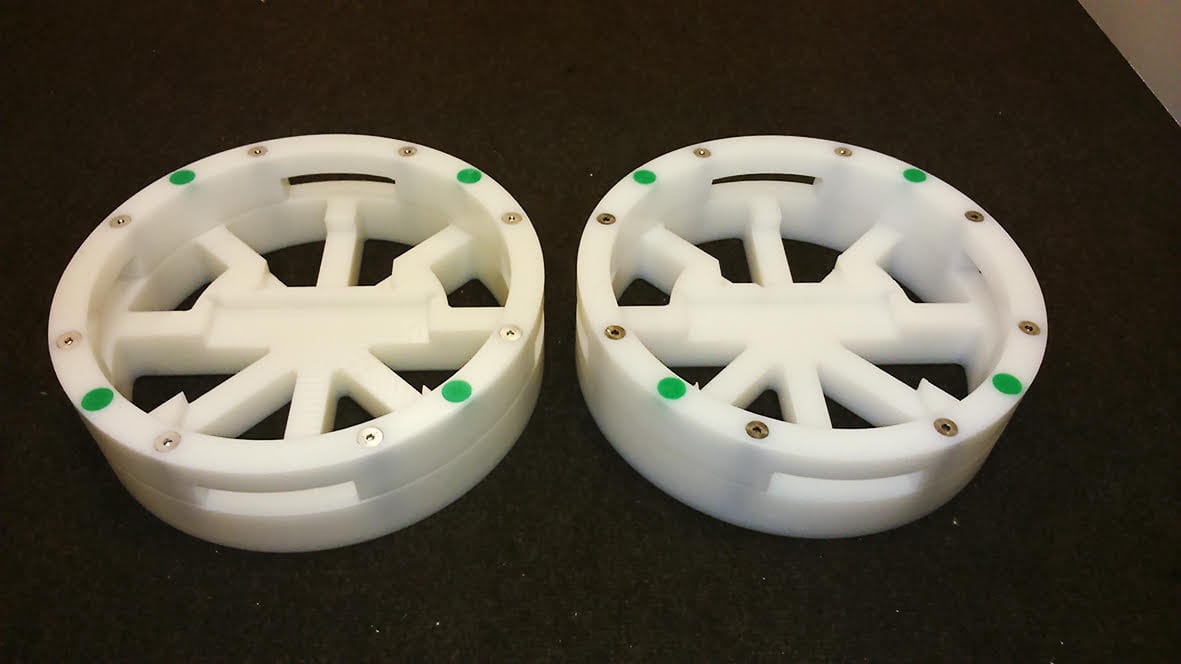

Many efforts have been undertaken by OEMs to remove costs from their products. Converting metal components to plastic components in an application can result in significant reductions in costs, design changes, overall weight and waste.

Today, plastic materials include an expanding variety of characteristics for tensile strength, heat tolerance, and chemical resistance. Because of these specialised characteristics, the number of plastic alternatives also continues to expand and can be found in an ever-increasing variety of applications. Plastic parts can also be polished to an optical finish when required. A quality not available when using metal.

One of the main advantages of using Plastic over Metal is the fact that Plastic does not corrode or rust and is lightweight. Within various applications, metals often need to be lubricated and can then cause problems with additional dust and grease build-up. This in turn creates further maintenance requirements for the material. Thermoplastics on the other hand, do not require any lubrication of any kind and therefore increases part life resulting in less downtime.